The BBS plate is easy enough to pop out. I used a tweezers.

Inside the wheel you see the lock nut detail. I was wondering how to keep this detail on the conversion and the answer was not to try. Instead I will use the ends of the axle to simulate it.

When you cut off the wheel at the depth you need, the center nut detail is left behind.

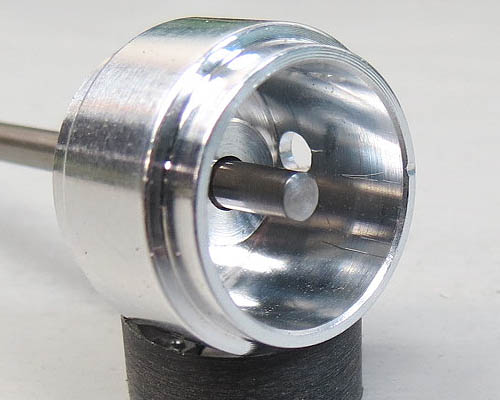

This is what you end up with.

Make sure to make a small notch on the insert to clear the screw/wrench access.

I cut the axles at a longer length so the axle itself would simulate the nut.

Not bad. Looks almost identical, especially when you are a foot away or at speed.