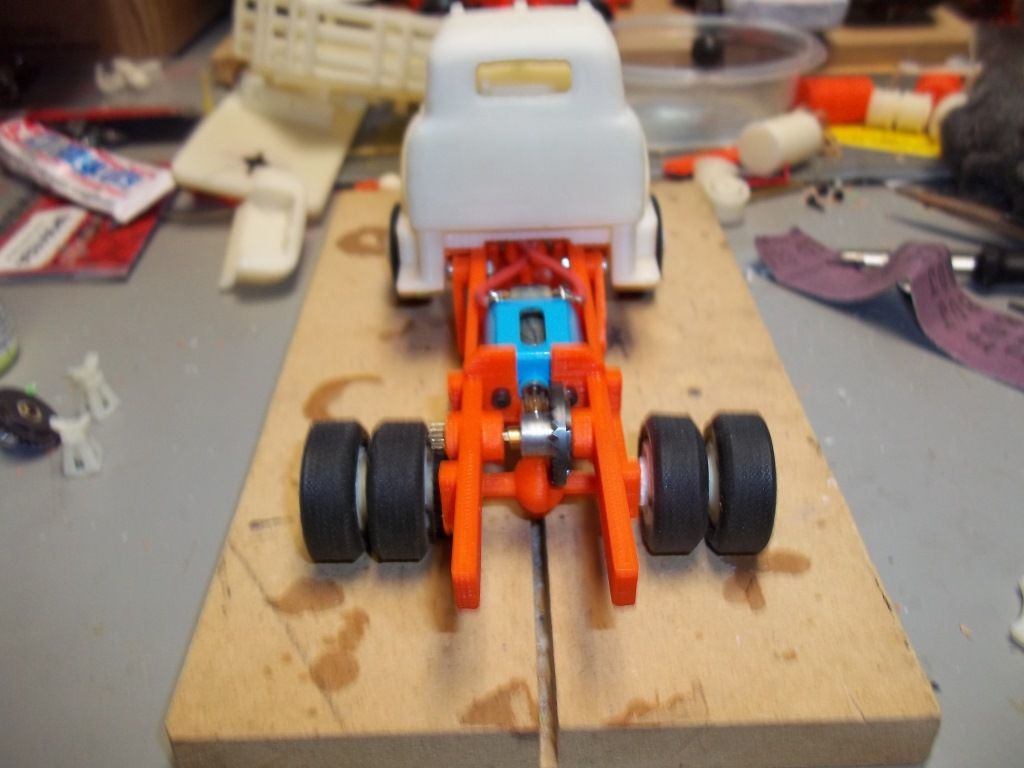

The I printed out a frame and decided on a drop flag for current transfer.

Once I got the chassis assembled I soon discovered that I didn't have a motor for the chassis. I wanted a motor of not more than 14k so an another order was placed at SCC.

To keep the speed down for proper cleaning, I used a double reduction setup. I went with a 9-27 on the crown gear and 11-36 on the sidewinder. I used some 3/32 tubing for the bushings in the top drive but if I had to do it again I would use brass rod and drill out the center on the lathe.

After a quick temp assembly it was time for a test run on the track.

I knew my track was dirty but didn't expect this.

Well I think this little test was successful for according to the track mate I was able to hold full throttle all the way around the track for an average speed of 80 mph. This thing actually cleaned better than the swifer mop that I normally used. What I did prior to the run was to give the pad a light spray of Endust, the dust magnet and run two laps per lane. Now to give it a paint job and add some 55 gallon drums and a couple of bags in the bed. Hopefully I have this done by this weekend.