by chrisguyw » Fri Oct 16, 2015 11:17 am

by chrisguyw » Fri Oct 16, 2015 11:17 am

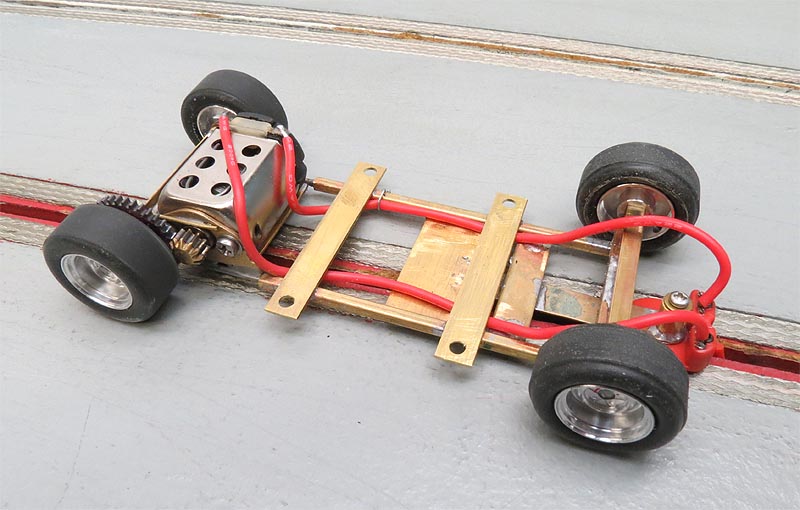

Harry, Bill is absolutely correct on the gap between the bottom of the motor bracket and your chassis rail.....I did not have the heart to mention this after you had gone to the work of taking my advice on the brace.

I think you can easily rectify this, and, incorporate another improvement at the same time..............you said that the motor rested on the bottom brass cross brace......well, ditch the bottom cross brace,.... unsolder the bracket/brace from the main rail.....screw the motor to the bracket, and place the assembly into the chassis so the motor bottom is flush with the chassis bottom...grind/file the bracket bottom so it is just meeting your chassis rail, with the motor bottom still flush.....tack solder the bracket and brace.....remove motor and complete the soldering.... re position your cross brace in front of the can so the trailing edge of the brace just meets the can front.

Re doing my chassis again??? :roll: ......a pain.......A lower cg, and a stronger chassis..................priceless!!! :dance:

To re iterate Bill's comments/advice......solder is weak/soft (just bend a piece) and any soldering joins that involve a gap are useless. The most important thing in building a strong chassis (assuming everything is clean/good flux/hot iron etc.) is to ensure that the various rails/plates/tubes are as "tight" as possible........it takes most builders (good ones) far longer to "fit" the pieces than to solder them........I know that we all want to see our creation finished, but, trust me, time spent on ensuring a "tight" fit between the parts is essential, if you want the chassis to stay together.

Cheers

Chris Walker

Last edited by

chrisguyw on Fri Oct 16, 2015 12:13 pm, edited 1 time in total.