Great job Harry!!!.........very close to jewelery :text-bravo: ....hard to believe you have never built a "winder"

If I may, a few suggestions for your next chassis (or to anyone contemplating a first sidewinder build.

1/ The JK brackets are a big help in building a sidewinder, but consider soldering it to the inside of your chassis rail, and, flush with the rail bottom. This will improve the strength, and will slightly lower your cg. This will require that you place your bottom brass chassis brace in front of the motor....you can butt this brace to the front of the motor can (temporarily installed), tack solder, and then remove the motor for final soldering. If needed, you can solder the motor to this brace for additional strength (I generally find a drop or two of Shoe Goo along this join is more than enough, and, much easier to remove).

2/ I would strongly suggest installing a brace from the top of the JK bracket to the rear axle tube.....this will help significantly in removing lateral flex at the top of the bracket, and will greatly improve motor/rear axle strength. A simple (elegant and efficient) way to do this is......use you dremel to cut a "flat" on the top "crown" of the JK bracket......make a simple "L" piece from wire, and solder this to the top of the bracket, and to the rear top of the axle tube.

3/ Try to leave a little more "meat" on your rear axle tube.....cut it to a "U" shape with the open end obviously facing the motor......this will provide much needed strength for the tube/bushing interface (I know it feels strong and the bushings will not come adrift, but, brass is soft and a rear end hit can easily put a bend into the bushing/tube joint, causing rear end binding).

By leaving a little more axle tube (particularly at the top/rear, you also have a nice area to solder your "L" bracket/axle tube brace.

Please do not (nor anyone) consider this a criticism of your work...it is really really nice!......I just wanted to pass along a few things that may help

Cheers

Chris Walker

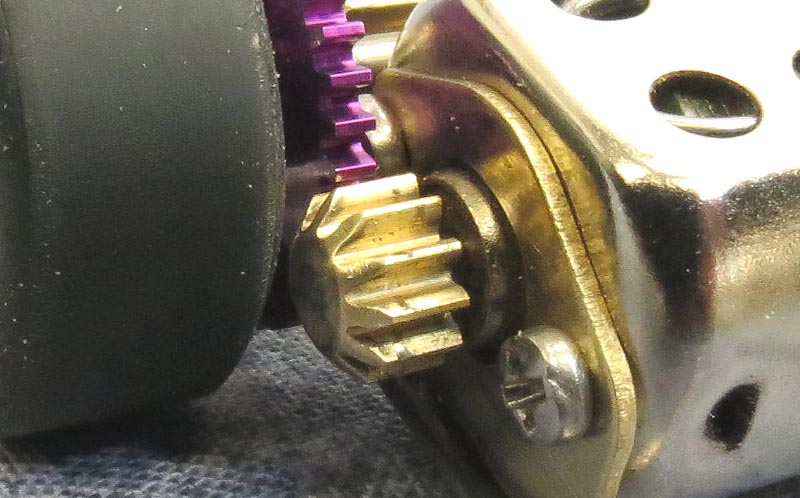

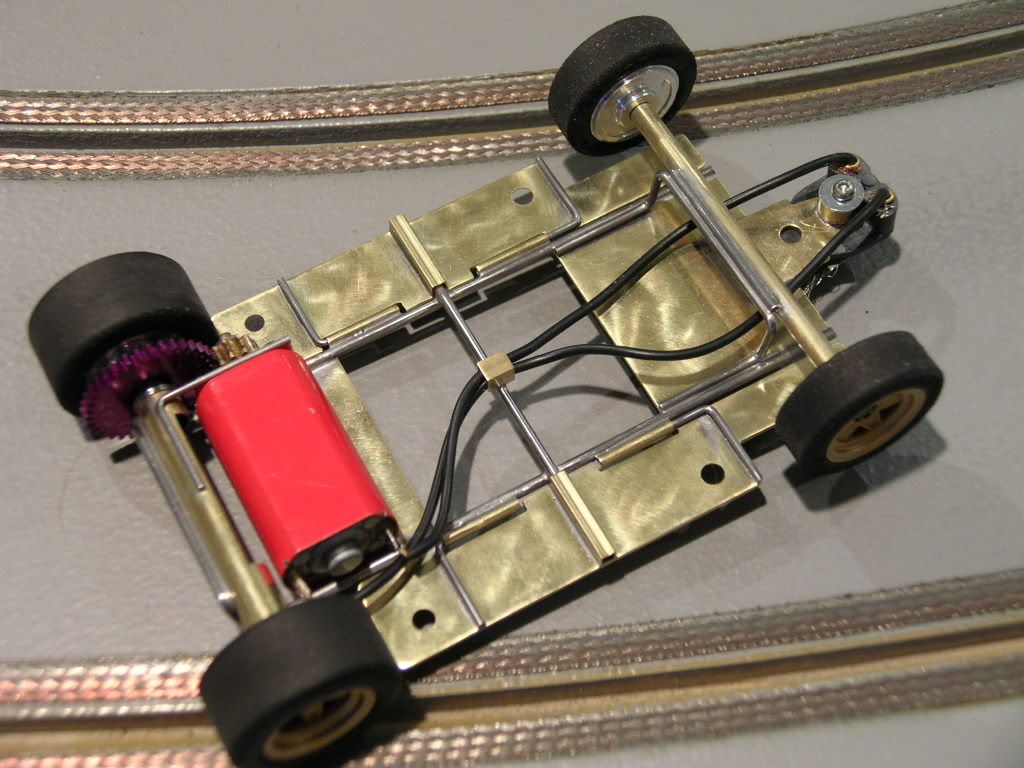

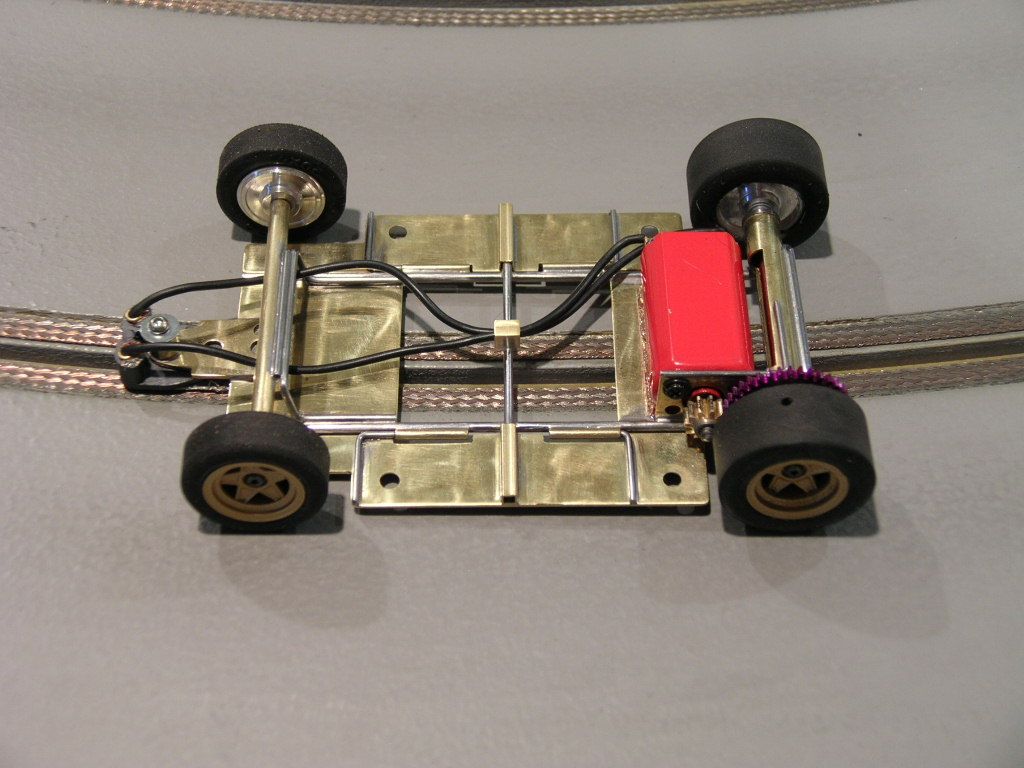

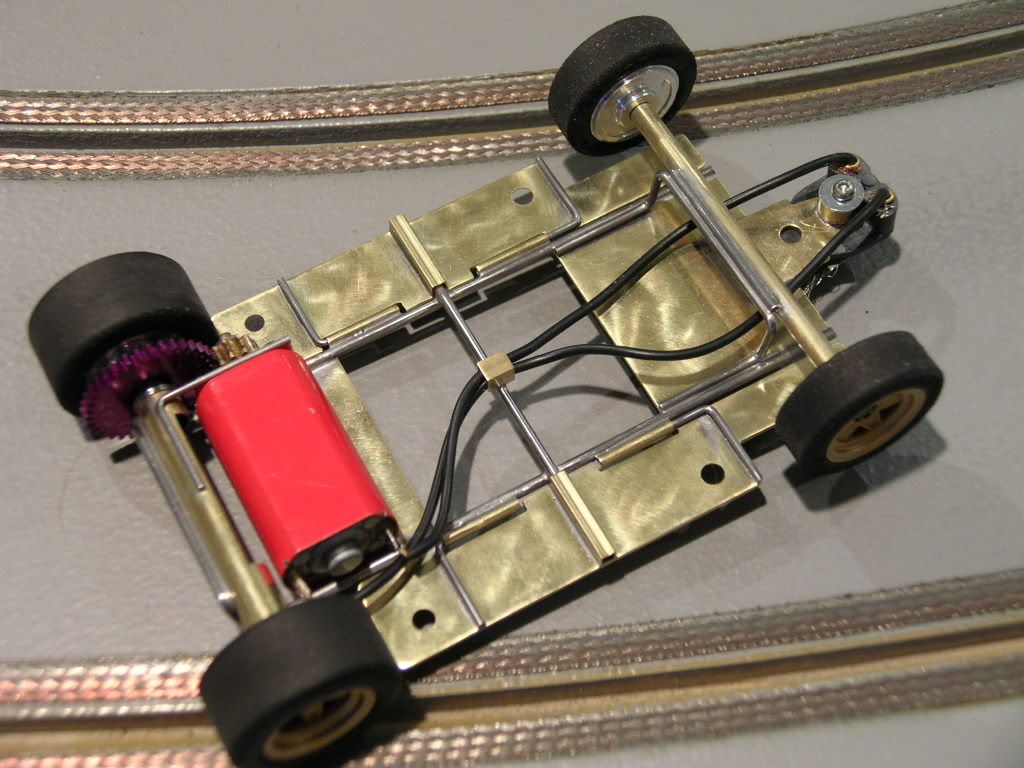

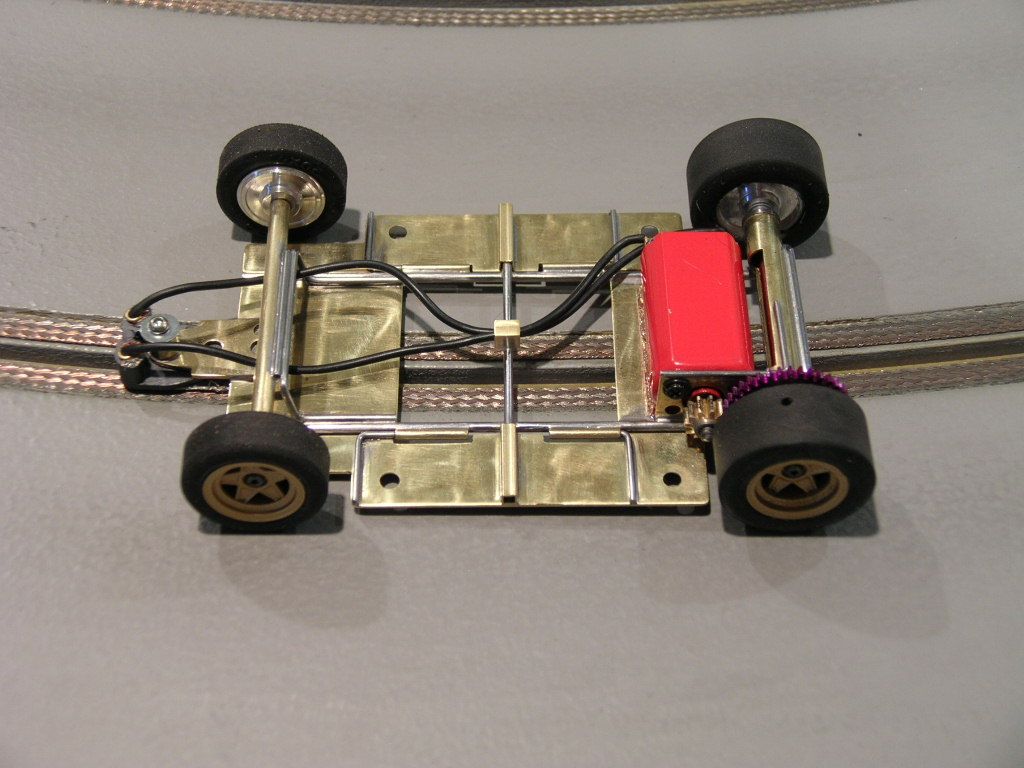

PS I just dug up these pics.,........a chassis done a few years ago, and with a FF050 motor, but, they will illustrate what I was vainly trying to describe above.

The first pic. shows the wire brace between the bracket top and the rear axle tube,....folks, this really helps!

The next shot shows how I have tried to leave as much of the rear axle tube intact as possible.........I know using a "130" motor will require more of the tube to be removed, but, try to only remove just enough for clearance. It also shows a bit of Shoe Goo between the motor and bottom chassis brace.......you can solder if you like, but for the motors we use, the "goo" is enough.......particularly when the bracket/axle tube is strengthened with a brace.

Hope this helps.....build on folks!!.....oh, Harry, over the years, more great chassis have been built using pliers, than with wire benders!! ;)

Cheers

Chris Walker