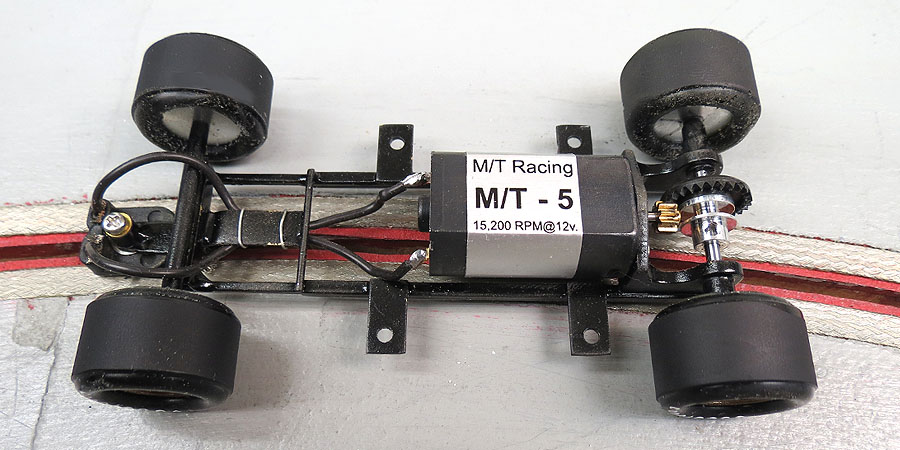

In my builds I measure and cut the tubing the length it needs to be to set the width of the rear wheels. This sets my side to side freeplay and no need for the motor shaft to rest inside the boss (groove) of the crown. My freeplay is set using the wheels. I adjust the wheel on one side until I have a freely spinning assembly.

Does the longer tubing on each end cause more friction than a bushing? Sure it does. Is how MUCH it causes that critical in my building? No.

I will run a axle through this with my drill and some polishing compound. When I am finished "honing", I can tilt this chassis and the axle will fall out faster than I can catch it. That is about as good as it gets to me.

I use this method because it's simple for me. No other reason. If I decide I want one of the wheels to sit a little wider, I use a small shim that SCC sells. If I need it to come inside, I use a flat file to reduce it. Some fine grit sandpaper deburrs the edges just fine.

The difference of this setup and using standard bushings with axle collars or spacers haven't cost me any wins. :)

So I am not disputing anything here. Also not saying my method is the way anyone should do it. Just how I like it. :)