by mattb » Wed Aug 19, 2015 7:08 am

by mattb » Wed Aug 19, 2015 7:08 am

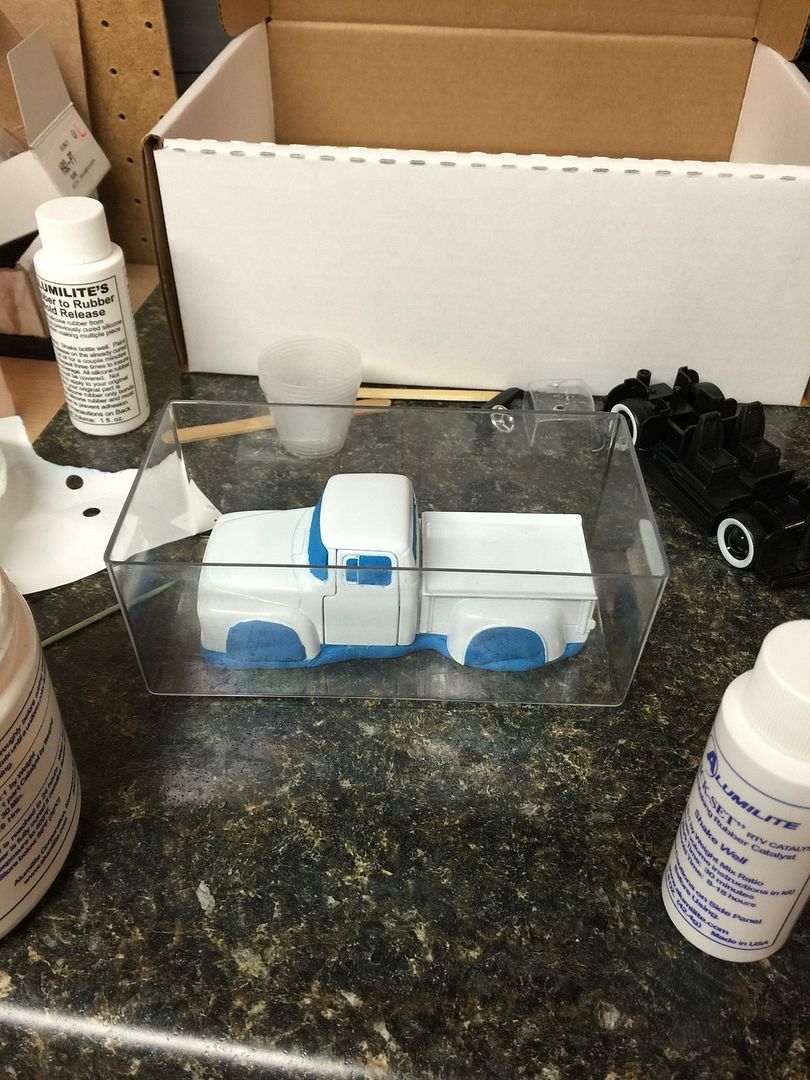

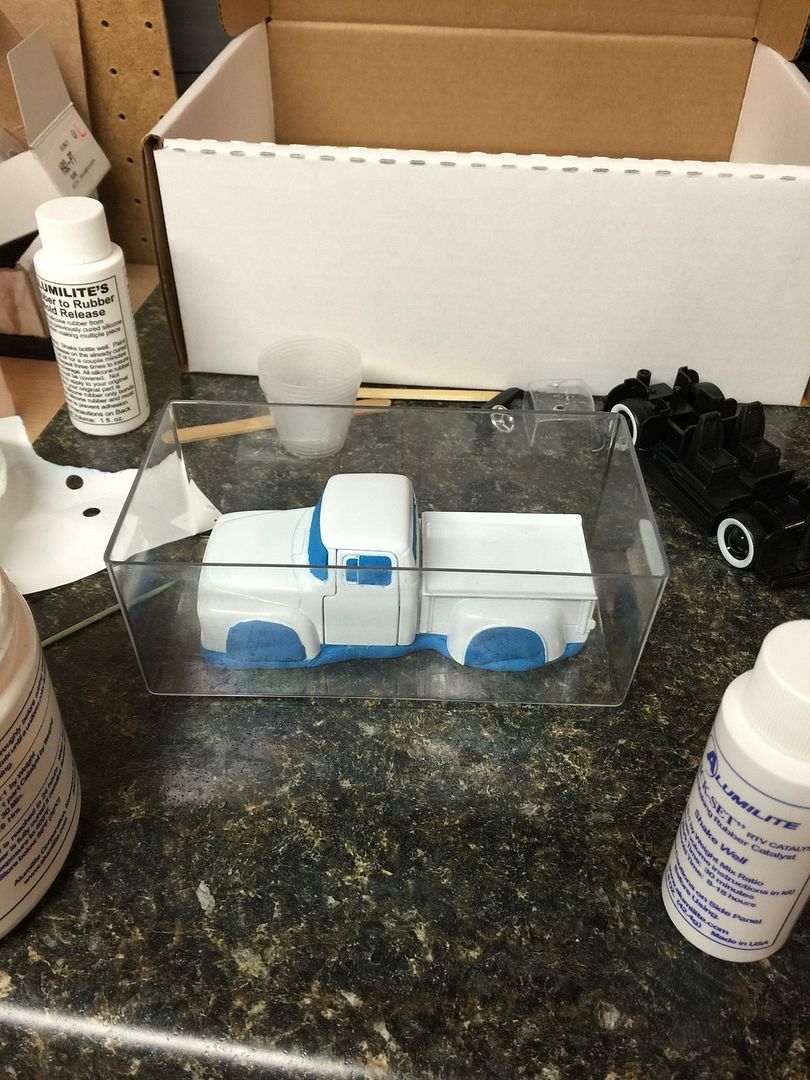

Another tip, allow at least 1/2 to 1 inch of clay below the body. Your inner plug will force resin out of the mold if you don't have that 1/2 inch or so of space above the cavity. After you cast a few, you may find a couple places that the resin doesn't easily flow to and there will be air pockets. Your best bet then is to cut some vents to allow the resin to more easily move into those parts of the mold. Two coats of silicone to silicone mold release before you do the inner plug, allow to dry at least 12 hours. Coat the whole outer mold, even where the body sets.

When you pour, rotate your mold so the resin covers the whole inside, then slowly push the inner plug in position.

If you want to skip the mold release inside your mold, a generous coating of talcum powder will work. Liberally coat the inside them blow out the excess. I will release easy and will leave a surface that is great for paint adhesion.

Plenty of guys on here that can help you along the way.