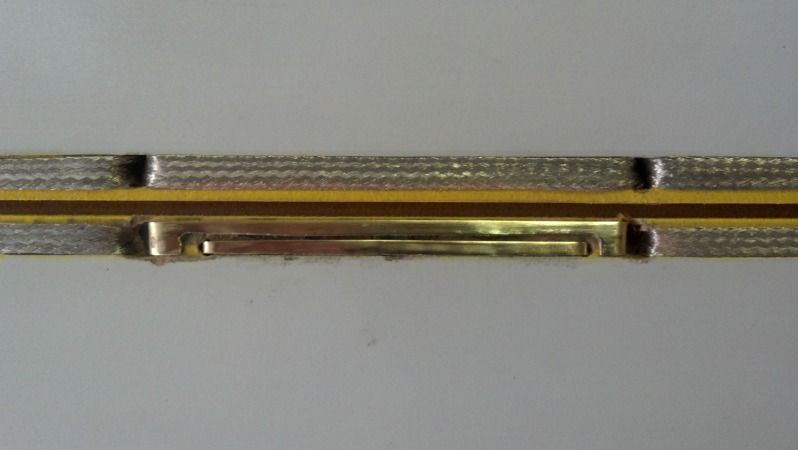

Then I tried another version of the inline dead strip using 1/4" wide brass strips. I was able to get the gaps down to 1/16" so the 1/32 car braid would bridge the gap and trigger the lap counter. This worked great with heavy 1/24 cars; didn't miss a lap count. However, a lighter car going over the dead strip would miss an ocasional lap. Even a heavier car that was accelerating and pulling the weight off the front end would miss a lap. I figured that the trigger area was so small that a car at speed could skip over it and not make contact. Worked OK but back to the drawing board.

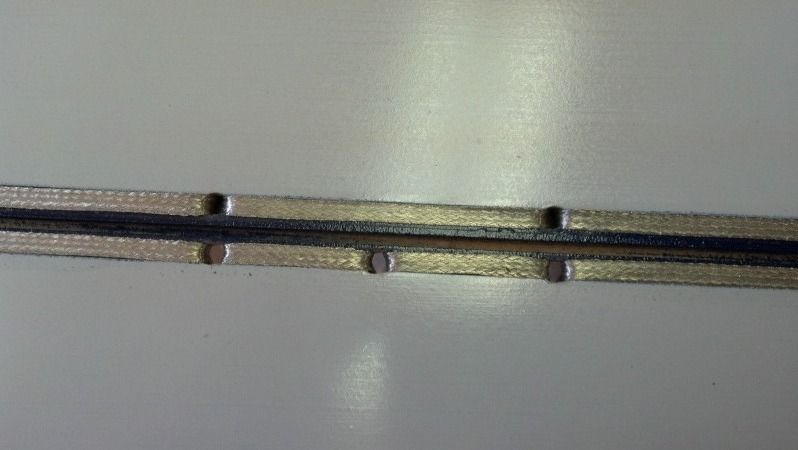

For my last effort at a dead strip I used another method that was explained on this board; a split rail dead strip. I used 1/4" wide brass strips, cut them down, bent them in a "U" shape, and pushed the ends through holes in the braid recess. The brass was super glued to the track and hot glued underneath the track. The gap between the two strips is about 1/32". I am happy to say that now this dead strip counts all laps for all cars! The longer contact area (about 3") gives the car braid more opportunity to trip the lap counter and works well with any length or width braid. I even ran some of my HO cars using Slide Guides on it and they counted every lap. I am now a happy camper....ah slotter! Hope this helps anyone try to put a dead strip on the track. I will be glad to answer any questions anyone has about getting this to work. I was really puzzled at first about getting a dead strip to work but it really is pretty simple.