Page 1 of 1

Roll cages...

Posted:

Fri Feb 13, 2015 12:57 pmby noddaz

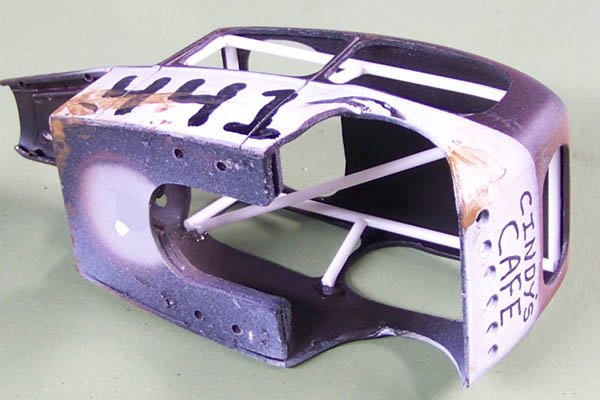

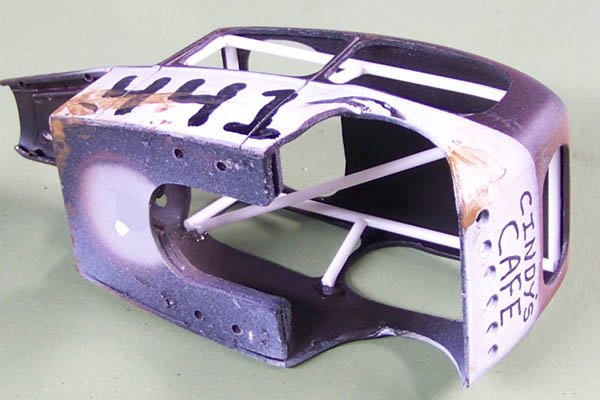

Roll cage question. The 33 resin build with cage:

Brought me to this question.

Anybody have a way to bend styrene plastic tubing for making roll cages? Cut corners on a cage just do not look right.

That brass is beautiful, but top heavy...

Scott

Re: Roll cages...

Posted:

Fri Feb 13, 2015 1:03 pmby turbokev

Maybe running the area you want to bend under hot water?

Then putting a bend in it and 'hardening' it under cold water?

Just a thought~

Re: Roll cages...

Posted:

Fri Feb 13, 2015 1:43 pmby racer6583

When I want to bend styrene of any thickness I take a glass baking dish put water in it.

Put it in the microwave and heat it up to where it is just a little to where you don't want to put your hand in. Then I keep checking to see if I can stand the temp of the water then see if the styrene is ready to bend then if it flexes with ease I bend it to the desired degree then I run cold water to lock in the shape.

I know this is the long way of doing this but I believe this way gives you more control in how you want your piece to look.

Than using a light or soldering irons. I used this method when I built static 1:25 / 1:24 competition models of cars and mods that weren't made by the model companies.

Either process will work thought you would like to know how I made roll cages for my static models.

Racer6583

Rex

P.S. PUT THE STYRENE IN THE WATER AFTER YOU heat the water please don't ask why thanks

Re: Roll cages...

Posted:

Fri Feb 13, 2015 1:59 pmby btaylor

Do not discount the type of cage you can build using straight pieces! it was used quite often by teams and individuals without deep pockets.

Re: Roll cages...

Posted:

Fri Feb 13, 2015 2:10 pmby waaytoomuchintothis

I use a 40w high intensity light bulb, stationary on the bench. I hold the ends of the styrene rod very close to the bulb but not touching, and roll it between my fingers, getting the heat even all around. In a very short time, the rod will begin to soften and I can transfer it to the paper that has the shape I want drawn on it. I bend it to that shape and hold it just a little while to get firm, and then dip it into cold water to set. Then I only have to cut off the ends that are not needed and that part is complete, including the mating surfaces at each end. It usually only takes about 20 minutes to make all the bits and assemble them. By the way, the styrene rods are from Evergreen.

Re: Roll cages...

Posted:

Fri Feb 13, 2015 2:44 pmby HomeRacingWorld

I use a lighter. Also use rod and not tubing.

Trail and error. As you can see, there are many ways to skin a...roll cage.

And Bob makes a good point. I have done both depending on the car. Sometimes I mount the bars inside the body itself and then just add the driver tray.

Re: Roll cages...

Posted:

Fri Feb 13, 2015 4:14 pmby KD11

I just purchased this soldering station that also provides adjustable heat and air flow for de-soldering smd devices. I tried it on the styrene for making a roll cage and with a little practice this worked very will and fast.

Re: Roll cages...

Posted:

Fri Feb 13, 2015 4:15 pmby noddaz

Ok, plastic rod... Tubing would collapse..

And thanks... Those ideas are great!

Scott

Re: Roll cages...

Posted:

Fri Feb 13, 2015 4:47 pmby TsgtRet

I guess I am "old school" (cheap, broke, etc). I keep a candle on my bench and save all of the properly sized sprue from the kits. With a little practice it works and I can save the expensive tube for axle carriers and exhaust pipes. Just remember: patience! hurry or get too close and it turns into melted cheese (without the flavor).