First, a bit of background.................A year or so ago MiniGrid ran a class for Gp. 5 cars, with the rules allowing only plastic chassis cars, but, chassis mods were allowed......including chassis stiffening. One of our customers/racers was intent on running a Fly Porsche 935 in the series.....Yes, one of the sidewinder cars with the motor behind the centerline of the rear axle!!!!!!

Out of the box, this configuration is not the hot ticket for competition....for a couple of reasons...1/ with all the motor weight behind the axle centerline, this configuration, thanks to the lever/fulcrum principals, really makes the front end light,......and, more critically,.... 2/ This chassis is about as longitudinally stiff as a piece of string, which causes severe axle tramping.....a really bad thing!!. (For all you builders/tuners, it is nearly impossible to have a chassis that is too stiff longitudinally)

As this racer was still really keen to run this car in the series, he asked me if I could do some work on the chassis, and the following pics. illustrate what was done. To keep a somewhat stock appearance, I used styrene sheet and styrene tube, glued in place with Locktite 380.

The car was competitive, and although not quite on pace with the "A" class cars, it did win a race or two (but not the series championship) in the "B" class, where this driver competed, and was smooth/quick and relatively vice free.

Hope some of this gives you some ideas/help, and If I have left out anything, please let me know.

Cheers

Chris Walker

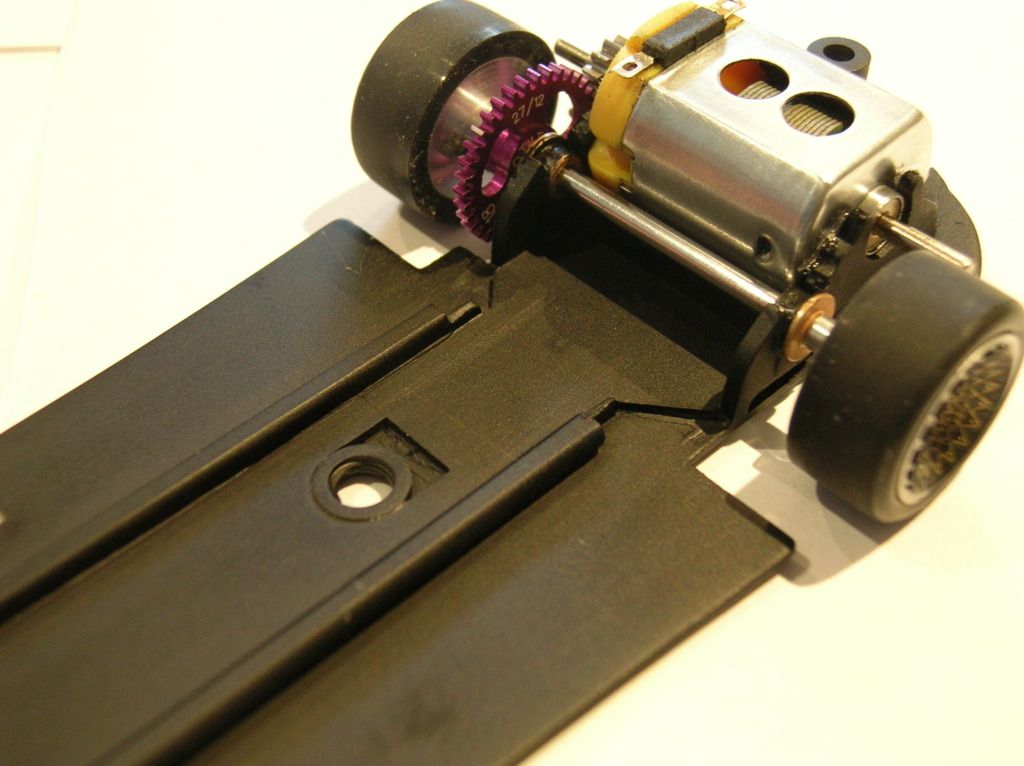

The first shot shows some 20. thou. styrene sheet, and some styrene tubing cut and glued to the chassis floor.....the tubing is the most significant addition to chassis stiffening, and also doubles as a neat way to route the lead wires. The chassis was straightened first, and then sanded to both look a little more finished, and to provide some "tooth" for the glue. By having the stiffening pieces closer to the chassis centerline, it provides longitudinal stiffness while still allowing torsional flex........a good thing!!

A shot of the front end.............

I did need to sand the tops of the styrene tubes for interior clearance, and added a quick shot of flat black spray to make it look a bit more finished

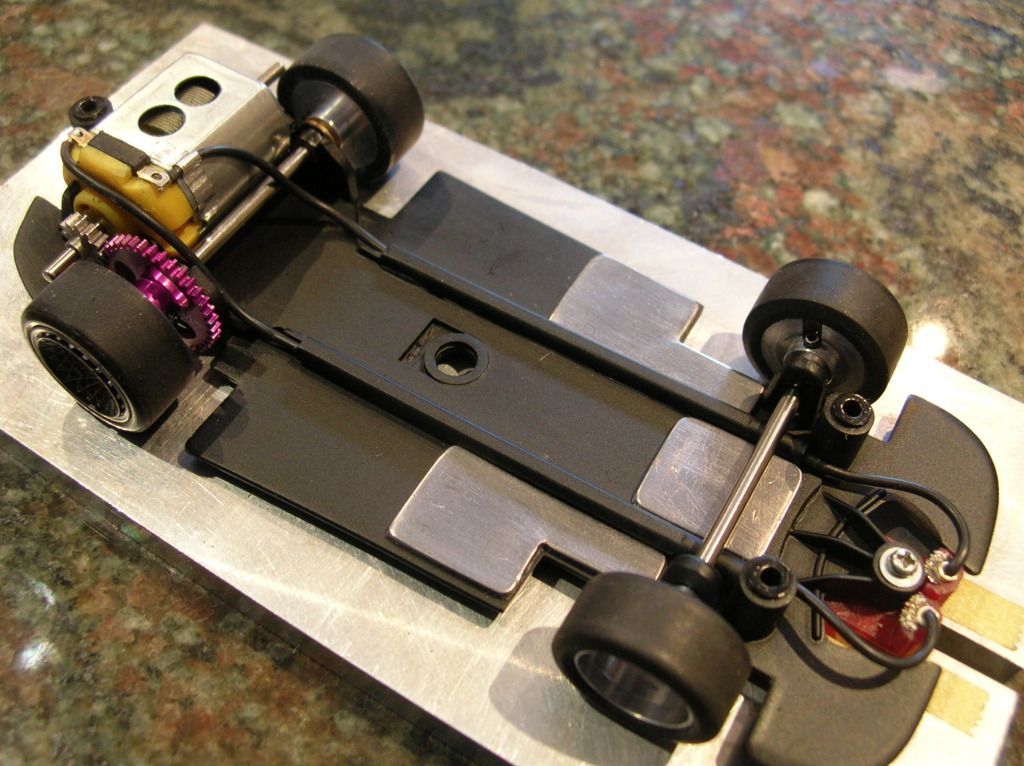

The finished rolling chassis...........a fair bit of front end ballast was required to compensate for that motor hanging out the back!!..........note the small urethane washers glued to the tops of the body mount tubes.........these reduce vibration/noise in the body/chassis interface.