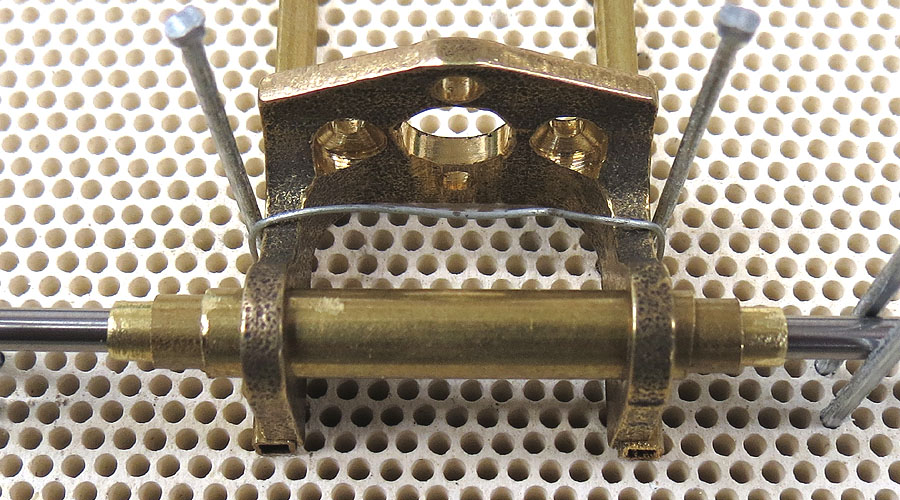

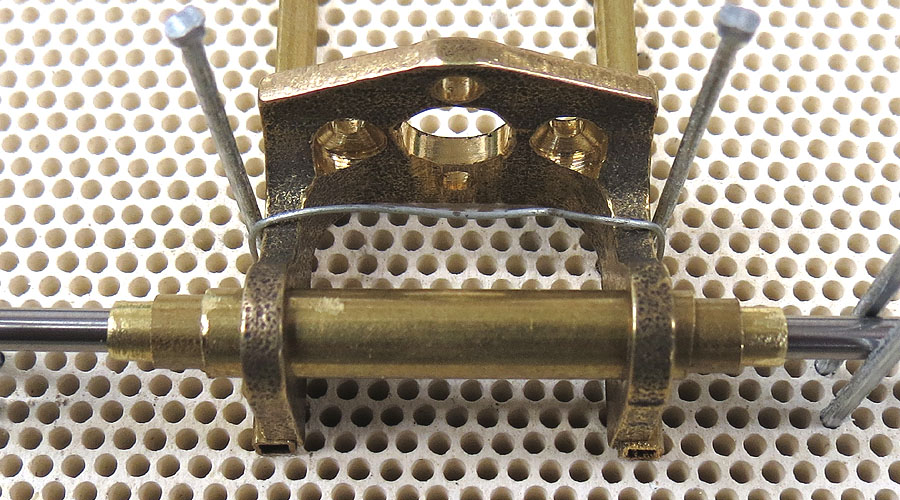

Chassis building on a honeycomb ceramic plate.

Chassis building on a honeycomb ceramic plate.

Last edited by Retro Racer 44 on Mon Jul 28, 2014 4:06 pm, edited 1 time in total.

- Retro Racer 44

- HRW SlotCar Veteran!

- Posts: 1385

- Joined: Mon Nov 18, 2013 4:37 pm

- Location: Maple Ridge, BC, Canada

Re: Chassis building on a honeycomb ceramic plate.

Thank you. Very well done.

-

HomeRacingWorld - HRW Janitor

- Posts: 15569

- Joined: Wed Aug 08, 2012 2:05 pm

- Location: HRW Skunkworks

Re: Chassis building on a honeycomb ceramic plate.

Nice job.

Two quick questions; how do you decide what height to set the axles so that you know the frame won't drag and how do you decide what height to set the frame from the track?

Ventura Alfa

Two quick questions; how do you decide what height to set the axles so that you know the frame won't drag and how do you decide what height to set the frame from the track?

Ventura Alfa

- VenturaAlfa

- HRW SlotCar Veteran!

- Posts: 318

- Joined: Wed Sep 05, 2012 7:15 pm

Re: Chassis building on a honeycomb ceramic plate.

I set the axle height based on the size of tires I plan to use. Generally I use the full 1/4 x 1/4 wood that I ripped from a 2 x 4 when I am using 15" scale wheels. I knew this build would need lower axles for the 13" scale wheels I plan to use. Usually my chassis are 1/16 to 3/32 from the track. Ideally I should be able to roll an axle underneath without touching the chassis.

There is a lot of trial and error to it, but you can get an idea by standing the wheel/tire up against the wood you are using to see how much space there is between the top of the wood and the axle hole, and then calculate what wood thickness you need. The flat surface of the board is where your chassis bottom will be.

There is a lot of trial and error to it, but you can get an idea by standing the wheel/tire up against the wood you are using to see how much space there is between the top of the wood and the axle hole, and then calculate what wood thickness you need. The flat surface of the board is where your chassis bottom will be.

Last edited by Retro Racer 44 on Tue Jul 29, 2014 1:05 am, edited 2 times in total.

- Retro Racer 44

- HRW SlotCar Veteran!

- Posts: 1385

- Joined: Mon Nov 18, 2013 4:37 pm

- Location: Maple Ridge, BC, Canada

Re: Chassis building on a honeycomb ceramic plate.

:music-rockout: :music-rockout: this is awesome! :text-thankyouyellow: :text-goodpost:

-

scatman - HRW SlotCar Veteran!

- Posts: 570

- Joined: Sun Feb 03, 2013 2:51 pm

- Location: South MS.

Re: Chassis building on a honeycomb ceramic plate.

Here is an idea I used from searching the web that works pretty good for holding some parts down.

Using craft wire you can find almost anywhere including Wallyworld.

Poke it down through the holes and just twist underneath to tighten.

The method Retro shows is outstanding and less tedious too. I bought this pack of assorted dowels at Wall World to have a variety of sizes.

Thanks for all the input, will be a great resource I think.

Using craft wire you can find almost anywhere including Wallyworld.

Poke it down through the holes and just twist underneath to tighten.

The method Retro shows is outstanding and less tedious too. I bought this pack of assorted dowels at Wall World to have a variety of sizes.

Thanks for all the input, will be a great resource I think.

-

HomeRacingWorld - HRW Janitor

- Posts: 15569

- Joined: Wed Aug 08, 2012 2:05 pm

- Location: HRW Skunkworks

Re: Chassis building on a honeycomb ceramic plate.

This is a great write up thank you for sharing!

Sent from my iPhone using Tapatalk

Sent from my iPhone using Tapatalk

-

ListerStormGT - HRW SlotCar Veteran!

- Posts: 1196

- Joined: Sun Sep 02, 2012 11:24 pm

- Location: Florida

Re: Chassis building on a honeycomb ceramic plate.

Retro, thanks for the tutorial, since reading it and seeing how its done, I ordered mine this afternoon.

Thanks

Bob

Thanks

Bob

-

chappy - Minister of Slot Racing

- Posts: 2926

- Joined: Fri Sep 28, 2012 5:22 pm

- Location: Ontario Canada

Re: Chassis building on a honeycomb ceramic plate.

Thanks Dave, but sharing is what these forums are all about, IMHO. I loved to be able to share this wisdom with others, as someone somewhere shared it with me a couple years ago. I do, however, like to see what others are building with their boards. I enjoyed the GENERAL's thread, and look forward to others as well.

Cheers,

Keith

Cheers,

Keith

- Retro Racer 44

- HRW SlotCar Veteran!

- Posts: 1385

- Joined: Mon Nov 18, 2013 4:37 pm

- Location: Maple Ridge, BC, Canada

- Retro Racer 44

- HRW SlotCar Veteran!

- Posts: 1385

- Joined: Mon Nov 18, 2013 4:37 pm

- Location: Maple Ridge, BC, Canada

- Retro Racer 44

- HRW SlotCar Veteran!

- Posts: 1385

- Joined: Mon Nov 18, 2013 4:37 pm

- Location: Maple Ridge, BC, Canada

Re: Chassis building on a honeycomb ceramic plate.

Retro,

Nice tutorial, thanks for taking the time to post. Methe and I bought similar ceramic boards based on you previous recommendations and were considering adding a guide slot and or central hold down screw. Any experience drilling or cutting? Seems soft, but abrasive!

JT

Nice tutorial, thanks for taking the time to post. Methe and I bought similar ceramic boards based on you previous recommendations and were considering adding a guide slot and or central hold down screw. Any experience drilling or cutting? Seems soft, but abrasive!

JT

Last edited by JT Previa on Sat Aug 02, 2014 7:56 pm, edited 1 time in total.

-

JT Previa - HRW SlotCar Veteran!

- Posts: 350

- Joined: Sat Jul 05, 2014 8:48 am

- Location: Cape Ann, Massachusetts

Re: Chassis building on a honeycomb ceramic plate.

The slot for the guide is a good idea, but not necessary with my method, as all I do is locate the tube for the guide.

If you had a 1/8 drill bit intended to drill ceramics, you could start in a hole and widen it out and then the next etc until you had a slot for the guide.

I have never tried to drill this material, but it will chip, so I'm guessing even a normal drill bit might work. Probably done best with a drill press where you don't have accidental sideways forces.

If you had a 1/8 drill bit intended to drill ceramics, you could start in a hole and widen it out and then the next etc until you had a slot for the guide.

I have never tried to drill this material, but it will chip, so I'm guessing even a normal drill bit might work. Probably done best with a drill press where you don't have accidental sideways forces.

Last edited by Retro Racer 44 on Sat Oct 04, 2014 12:34 am, edited 1 time in total.

- Retro Racer 44

- HRW SlotCar Veteran!

- Posts: 1385

- Joined: Mon Nov 18, 2013 4:37 pm

- Location: Maple Ridge, BC, Canada

Re: Chassis building on a honeycomb ceramic plate.

Use a masonry bit and go very slowly. Its just unglazed ceramic material, so the same tools used the same way will do what you want, but remember, ceramic is not only fragile to begin with, it makes hundreds of little fractures when you tool it. Frankly, I don't recommend messing around with a good thing, ya know?

-

waaytoomuchintothis - "Seasoned SlotRacer"

- Posts: 7576

- Joined: Wed Aug 29, 2012 7:16 pm

- Location: Chesterfield, Virginia

Re: Chassis building on a honeycomb ceramic plate.

One alternative would be to have someone turn you a post the same diameter as the guide's post you're using. About a 1/2" long in brass or aluminum is all you'd need. In the middle of this post's diameter, drill a hole through the same size as your 18 ga. nails. Now you can move your guide to any position on the honeycomb plate by sticking an 18 ga. nail through your turned post & positioning it wherever you want. No ceramic drilling or grinding would be involved.

- bill from nh

- HRW SlotCar Veteran!

- Posts: 373

- Joined: Wed Sep 05, 2012 5:32 pm

- Location: New Boston, NH

Return to The Marty Stanley Scratchbuilders Shop

Who is online

Users browsing this forum: No registered users and 47 guests